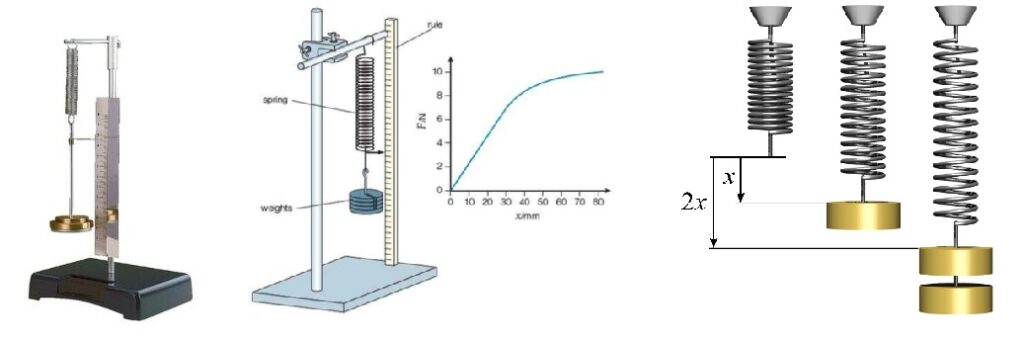

Helical Spring Apparatus.

What is the Hooke’s law apparatus spring?

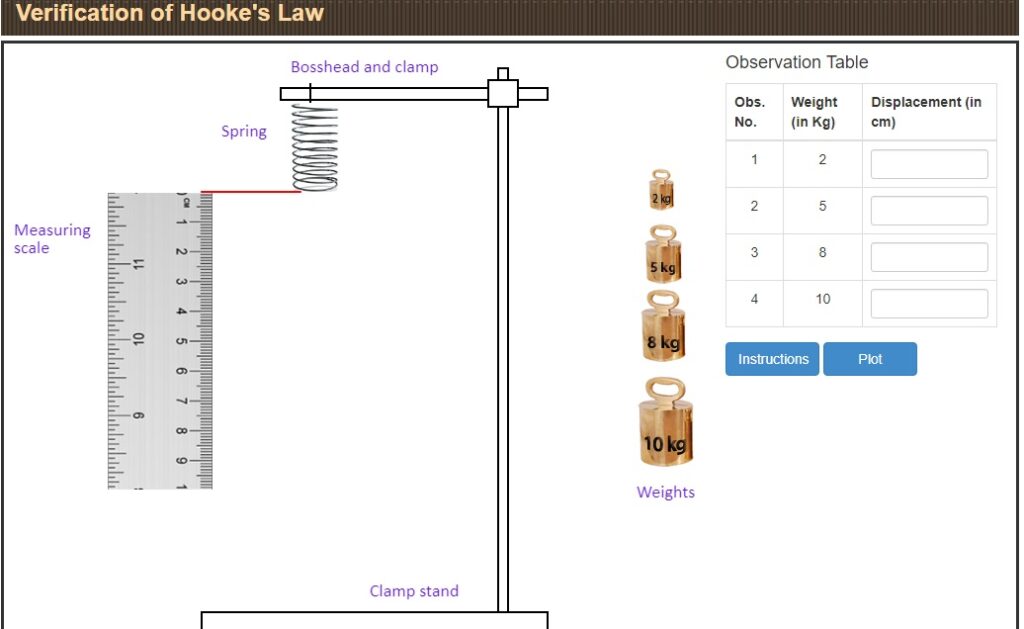

Ideal for verifying Hooke’s Law, that the elongation of the spring is directly proportional to the force applied, this apparatus is constructed to stand up to years of classroom use. It includes a precise mirror scale, which eliminates the errors in measurement caused by parallel.

Objective

To verify Hooke’s law – Hooke’s law states that the extent to which an elastic material will change size and shape under stress is directly proportional to the amount of stress applied to it.

Theory

An ideal spring is remarkable in the sense that it is a system where the generated force is linearly dependent on how far it is stretched, this behavior is described by Hooke’s law. According to Hooke’s Law stated above that to extend a spring by an amount dx from its previous position, one needs a force F which is determined by F = kdx. Here k is the spring constant which is a quality of each spring. Therefore, in order to verify Hooke’s Law, you must verify that the force F and the distance at which the spring is stretched are proportional to each other (that just means linearly dependent on each other), and that the constant of proportionality is k.

VIVA

1) | On hanging a mass through a spring will oscillate along the point where mg = -kx. | |||||

| FalseTrue | ||||||

| 2) | If the mass of the weight hanged on the spring is ‘x’ then () will be the force applied on the spring. | ||||

| 3) | After plotting the graph of the relation (Force applied vs Increase in length) should represent | |||||

| A straight lineA circleAn asymptote to the y axis | ||||||

| 4) | The likely force which prevents the spring from oscillating forever could be | |||||

| Magnetic field of the earth.Frictional force.Electric field due to static current. | ||||||

| 5) | Mathematically, Hooke’s law is stated as | |||||

| F=−kx, where x is the displacement, F is the restoring force, and k is spring constantF=kx, where x is the displacement, F is the restoring force, and k is spring constantF=−k/x, where x is the displacement, F is the restoring force, and k is spring constant1/F=−kx, where x is the displacement, F is the restoring force, and k is spring constant | ||||||

Some good references available online :

- Video Lecture on Hooke’s Law (Khan’s Academy)

- Determining the Spring Constant

- Encylopedia Britanica – Hooke’s Law (Theory)

- Hooke’s Law Experiemnt (Tutor Vista)

- Another useful video lecture

INVESTIGATING WIRES AND FIBRES

⇒ Nearly all materials show Hooke’s law behaviour up to a point

- This includes metals such as copper and steel, fibres such as cotton and silk, natural rubbers and polymers

⇒ The applied force beyond which materials no longer obey Hooke’s law will be different for each material

- In a school laboratory it is possible to investigate the properties of materials such as copper wire and nylon thread

- These materials produce measurable extensions for an easily obtainable range of applied forces

- Other materials, such as steel wire, require much larger forcs and so specialist equipment is required

⇒ Wires obey Hooke’s law because the bonds between the metal atoms act like springs

- When the wire is stretched the bonds lengthen slightly. When the force is removed, the bondsreturn to their original length

- However, if the force applied is too great, and the elastic limit exceeded, then the metal atoms will be able to move past one another and the wire lengthens

- This is known as ductility, and is a very useful property as it allows metals to be formed into thin wires – ductile behaviour is an example of plastic deformation

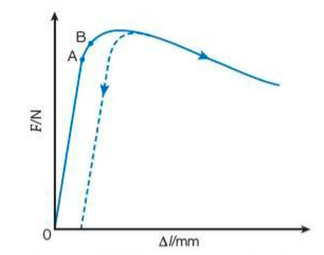

⇒ The dotted line on this graph represents the extension measured once the force is removed from the loaded wire

- It can be seen that the wire has permanently lengthened because, even with no applied force, there is still a measurable extension

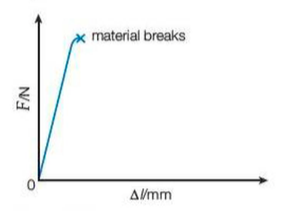

⇒ Some materials do not show plastic behaviour but are brittle and break when the elastic limit is exceeded

- Cast iron and glass are two examples of brittle materials

- The following graph shows a typical force-extension graph for high-carbon steel, which is also a brittle material

- The material fractures and breaks; it does not show plastic behaviour

⇒ The way in which ductile and brittle materials fracture is also different

- In a ductile material, the sample of material will elongate and ‘neck’ before it breaks – on a force-extension graph, necking occurs in the plastic region of the graph

- In a brittle material there is no change in the shape of the material because it does not undergo plastic behaviour – a straight break in the material is seen

- The below image shows the differnce between the two types of fracture