Filtration is to block suspended particles in liquid with membrane filters or porous materials, thereby separating solid and liquid substances in a heterogeneous mixture to perform separation and clarification. There are 3 common methods of laboratory filtration: by gravity, by vacuum and by pressure. Appropriate filtration method is to be selected according to the characteristics of the filtration sample, the removal efficiency of suspended particles, and the time spent on filtration.

Vacuum Filtration Principles

Vacuum filtration is also known as negative pressure filtration, reduced pressure filtration or suction filtration. Vacuum filtration is to create negative pressure in the container underneath the membrane and accelerate liquid to pass through the membrane to separate solid from liquid.

Vacuum Filtration Setup

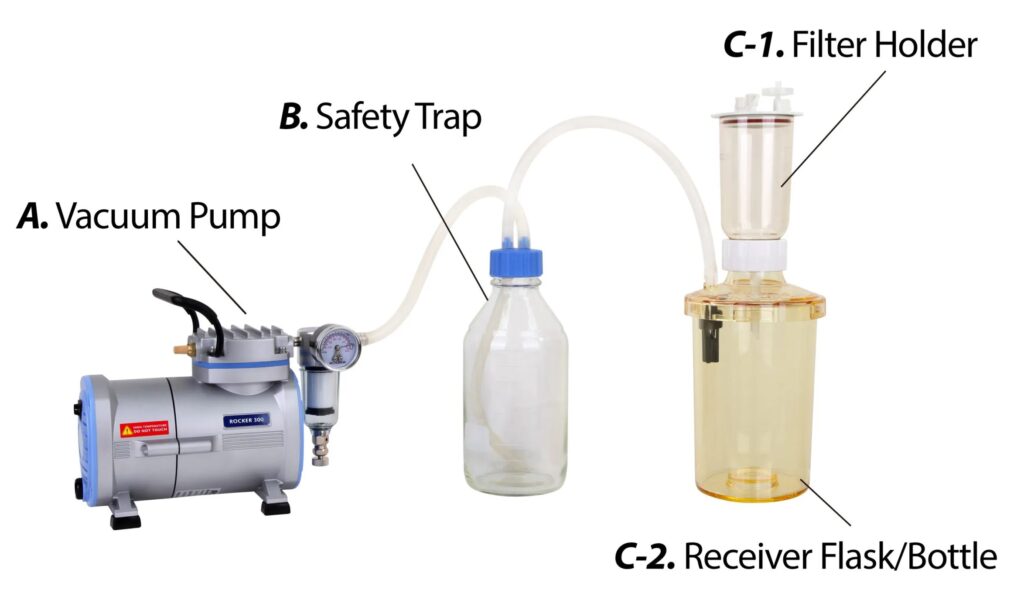

Vacuum filtration setup often includes vacuum pump, safety trap, filter holder and receiver flask.

A. Vacuum Pump

The vacuum pump used in vacuum filtration is to extract the gas molecules in a specific space (usually a lab flask or bottle) to reach a certain pressure difference and accelerate filtration. Generally, a pump with vacuum of 685 mmHg is capable of performing most filtration experiments because 685 mmHg represents a pressure difference of 90%. Only few experiments may require pumps with higher vacuum. (* 1 atmosphere is 760 mmHg)

How to select a proper lab vacuum pump?

- Select type of the pump by defining the sample whether it’s general water solution, organic solvent, or corrosive.

Watch to learn how to choose a right pump for your lab. - Choose proper vacuum according to the state of the sample, such as the amount of suspended particles, the viscosity of the liquid, etc. Generally, more viscous or more impurity samples needs higher vacuum to obtain satisfactory results.

Having problems with vacuum conversion? Lean how to do correct vacuum conversion. - Choose proper pump flow capacity based on the volume of the filter bottle. The larger the filter bottle is, the higher flow rate is required.

B. Safety Trap

The safety trap is usually installed between the pump and the receiver bottle in a vacuum filtration system. Use of a safety trap is to prevent filtrate from flowing back into the pump due to improper operation, which may cause damage to the pump. A safety trap in laboratory filtration system can be a GL45 glass storage bottle, vacuum bottle or waste bottle.

How do you protect pumps from liquid damage? Prote™ Filter Cartridge (YouTube video link)

C. Filter Holder

Filter holders hold filter membranes and ensure liquid to pass through the membrane for filtration. Filter holders can be fixed on top of receiver bottles with silicone stoppers or spin lock mechanism.

D. Receiver Flask

Receiver flasks are the containers connected to vacuum pump and collect filtrate, also known as suction flask or waste flask. They’re sometimes connected with a safety trap with silicone tubes.

How to select proper filter holders and receiver flasks?

- Filter holders are to be chosen based on the volume of sample. Common size of filter holder includes 25 mm, 47 mm and 90 mm (in diameter). The larger the volume of sample, the larger size holder is suggested.

- Material of filter holder and receiver flasks should be selected according to chemical characteristics of sample solvent(s). For more information, please refer to chemical compatibility chart.

Read more: Rocker Vacuum Filter Holders (Appendix 3)

Vacuum Filtration Application(s)

- Aqueous solution filtration, such as suspended solids, microorganisms, etc.

- Clarification of cell culture media and buffers.

- Separation of chemical synthesis.

- Roughing filtration of industrial solvent.

Literature references

| Literature | Author | Method applied |

| Cryopreservation of the gorgonian endosymbiont Symbiodinium | Gabriella Chong et al. | Seawater filtration (filtered seawater (FSW) preparation) |

| First instance of settlement by cryopreserved coral larvae in symbiotic association with dinoflagellates | Luca Cirino et al. | Seawater filtration (filtered seawater (FSW) preparation) |

| Detection and characterization of small-sized microplastics (≥ 5 µm) in milk products | Paulo A. Da Costa Filho et al. | Milk sample filtration |

| Solvent polarity mediates phytochemical yield and antioxidant capacity of Isatis tinctoria | Abdul Wakeel et al. | Vacuum drying |